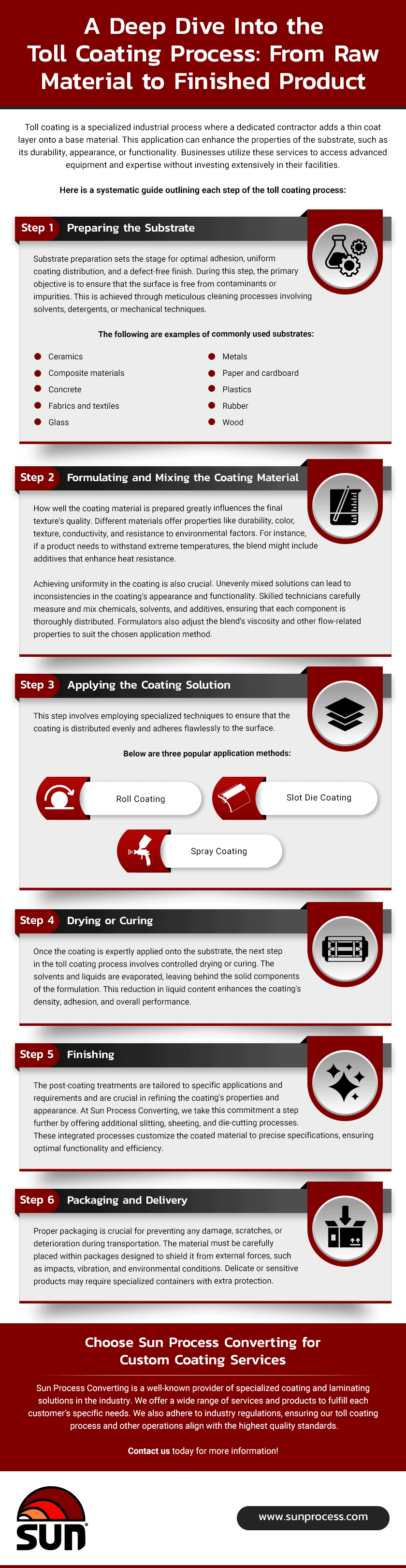

Toll coating is a specialized industrial process where a dedicated contractor adds a thin coat layer onto a base material. This application can enhance the properties of the substrate, such as its durability, appearance, or functionality. Businesses utilize these services to access advanced equipment and expertise without investing extensively in their facilities.

Here is a systematic guide outlining each step of the toll coating process:

Step 1: Preparing the Substrate

Substrate preparation sets the stage for optimal adhesion, uniform coating distribution, and a defect-free finish. During this step, the primary objective is to ensure that the surface is free from contaminants or impurities. This is achieved through meticulous cleaning processes involving solvents, detergents, or mechanical techniques.

The following are examples of commonly used substrates:

- Ceramics

- Composite materials

- Concrete

- Fabrics and textiles

- Glass

- Metals

- Paper and cardboard

- Plastics

- Rubber

- Wood

Step 2: Formulating and Mixing the Coating Material

How well the coating material is prepared greatly influences the final texture’s quality. Different materials offer properties like durability, color, texture, conductivity, and resistance to environmental factors. For instance, if a product needs to withstand extreme temperatures, the blend might include additives that enhance heat resistance.

Achieving uniformity in the coating is also crucial. Unevenly mixed solutions can lead to inconsistencies in the coating’s appearance and functionality. Skilled technicians carefully measure and mix chemicals, solvents, and additives, ensuring that each component is thoroughly distributed. Formulators also adjust the blend’s viscosity and other flow-related properties to suit the chosen application method.

Step 3: Applying the Coating Solution

This step involves employing specialized techniques to ensure that the coating is distributed evenly and adheres flawlessly to the surface. Below are three popular application methods:

Roll Coating

This technique passes the substrate through a series of rollers, which are partially immersed in the coating material. A controlled blend amount is transferred onto its surface as the object moves through the system. Roll coating is particularly suited for applications requiring precise control over coating thickness and a high degree of uniformity.

Slot Die Coating

This method positions a specialized die with a narrow slot close to the substrate’s surface. The coating is pumped through the space, creating a controlled flow that adheres to the material as it moves underneath. Electronics, optics, and flexible packaging often utilize slot die coating to ensure high-quality results.

Spray Coating

Spray coating is a versatile application method that atomizes the substance and directs it towards the surface. The formulation is often done using air spraying or electrostatic painting. These dispersed droplets stick to the substrate and form a homogeneous layer.

Step 4: Drying or Curing

Once the coating is expertly applied onto the substrate, the next step in the toll coating process involves controlled drying or curing. The solvents and liquids are evaporated, leaving behind the solid components of the formulation. This reduction in liquid content enhances the coating’s density, adhesion, and overall performance.

Step 5: Finishing

The post-coating treatments are tailored to specific applications and requirements and are crucial in refining the coating’s properties and appearance. At Sun Process Converting, we take this commitment a step further by offering additional slitting, sheeting, and die-cutting processes. These integrated processes customize the coated material to precise specifications, ensuring optimal functionality and efficiency.

Step 6: Packaging and Delivery

Proper packaging is crucial for preventing any damage, scratches, or deterioration during transportation. The material must be carefully placed within packages designed to shield it from external forces, such as impacts, vibration, and environmental conditions. Delicate or sensitive products may require specialized containers with extra protection.

Choose Sun Process Converting for Custom Coating Services

Sun Process Converting is a well-known provider of specialized coating and laminating solutions in the industry. We offer a wide range of services and products to fulfill each customer’s specific needs. We also adhere to industry regulations, ensuring our toll coating process and other operations align with the highest quality standards.

Contact us today for more information!