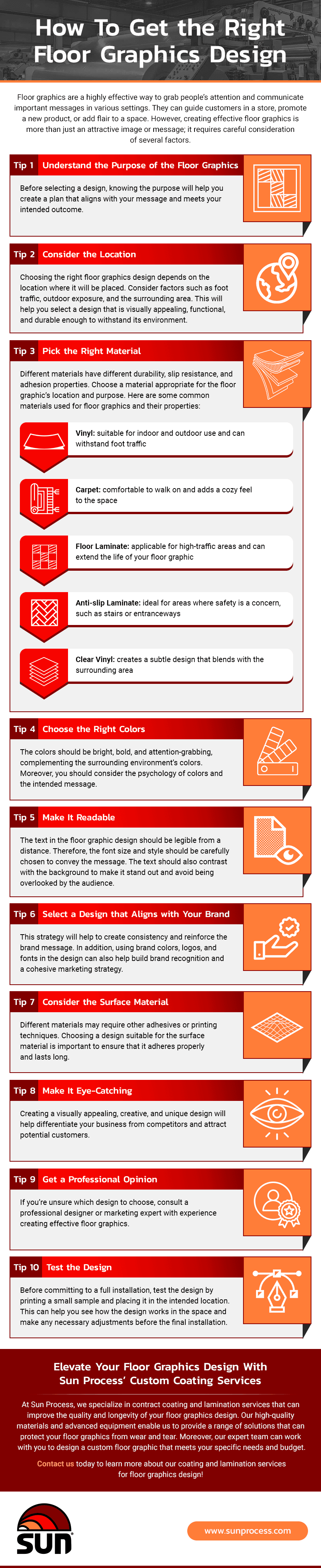

How To Get the Right Floor Graphics Design

Floor graphics are a highly effective way to grab people’s attention and communicate important messages in various settings. They can guide customers in a store, promote a new product, or add flair to a space. However, creating effective floor graphics is more than just an attractive image or message; it requires careful consideration of several factors.

This article will provide tips on selecting the right floor graphics design for your business needs.

Tip 1: Understand the Purpose of the Floor Graphics

Before selecting a design, knowing the purpose will help you create a plan that aligns with your message and meets your intended outcome.

Tip 2: Consider the Location

Choosing the right floor graphics design depends on the location where it will be placed. Consider factors such as foot traffic, outdoor exposure, and the surrounding area. This will help you select a design that is visually appealing, functional, and durable enough to withstand its environment.

Tip 3: Pick the Right Material

Different materials have different durability, slip resistance, and adhesion properties. Choose a material appropriate for the floor graphic’s location and purpose. Here are some common materials used for floor graphics and their properties:

- Vinyl: suitable for indoor and outdoor use and can withstand foot traffic

- Carpet: comfortable to walk on and adds a cozy feel to the space

- Floor laminate: applicable for high-traffic areas and can extend the life of your floor graphic

- Anti-slip laminate: ideal for areas where safety is a concern, such as stairs or entranceways

- Clear vinyl: creates a subtle design that blends with the surrounding area

Tip 4: Choose the Right Colors

The colors should be bright, bold, and attention-grabbing, complementing the surrounding environment’s colors. Moreover, you should consider the psychology of colors and the intended message.

Tip 5: Make It Readable

The text in the floor graphic design should be legible from a distance. Therefore, the font size and style should be carefully chosen to convey the message. The text should also contrast with the background to make it stand out and avoid being overlooked by the audience.

Tip 6: Select a Design That Aligns With Your Brand

This strategy will help to create consistency and reinforce the brand message. In addition, using brand colors, logos, and fonts in the design can also help build brand recognition and a cohesive marketing strategy.

Tip 7: Consider the Surface Material

Different materials may require other adhesives or printing techniques. Choosing a design suitable for the surface material is important to ensure that it adheres properly and lasts long.

Tip 8: Make It Eye-Catching

Creating a visually appealing, creative, and unique design will help differentiate your business from competitors and attract potential customers.

Tip 9: Get a Professional Opinion

If you’re unsure which design to choose, consult a professional designer or marketing expert with experience creating effective floor graphics.

Tip 10: Test the Design

Before committing to a full installation, test the design by printing a small sample and placing it in the intended location. This can help you see how the design works in the space and make any necessary adjustments before the final installation.

Elevate Your Floor Graphics Design With Sun Process’ Custom Coating Services

At Sun Process, we specialize in contract coating and lamination services that can improve the quality and longevity of your floor graphics design. Our high-quality materials and advanced equipment enable us to provide a range of solutions that can protect your floor graphics from wear and tear. Moreover, our expert team can work with you to design a custom floor graphic that meets your specific needs and budget.

Contact us today to learn more about our coating and lamination services for floor graphics design!