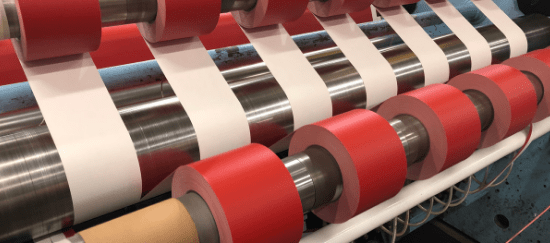

Since 1970, Sun Process Converting, Inc. has been a leading provider of custom coating and converting services for a wide range of pressure sensitive materials. Our capabilities include industrial roll slitting and rewinding services for industries such as aerospace, construction, medical, and many more. Our various slitting methods, combined with our material expertise, and full line of advanced machinery allows us to provide cost effective solutions that meet strict quality requirements.

Slitting and Rewinding Capabilities

Our precision slitting services guarantee a high degree of accuracy and versatility providing rolls in virtually any width and length which can be used for assembly, label stock, decorative trim and much more.

We keep above average tolerances which ensures that our slit materials can meet any critical dimension requirements. We can provide slit widths as narrow as .0625” up to 80” wide for material thicknesses from .5 mils to 50 mils. Our rolls have a maximum diameter of 40” and a maximum weight of 1,500 lbs. Our standard core sizes are either 3” or 6” and have the option for other core sizes which are available upon request. The materials that we work with include, but are not limited to:

- Adhesive Tapes

- Industrial Aluminum Foil

- Cloths

- Cork

- Felt

- Foam

- Paper

- Pressure Sensitive Products

- Stainless Steel

- Masking

- Medical

- Teflon

- VHB

We employ a variety of slitting and rewinding methods, which include:

Score

Score cuts, otherwise known as crush cuts, use a dull knife to crush the material against a flat surface and sever it.

Rotary

Rotary shear slitting processes use a mold slide plate and a cutting table along with longitudinal and transverse motorized cutting devices to create highly precise cuts. This efficient and reliable process is ideal for cutting sheet material.

Razor

Razor slitting is similar to scoring but uses a much sharper blade that cuts material above a groove or in the air rather than against a flat surface. Because the razor is sharp, it can create precise, narrow cuts. This method works best with light and non-abrasive materials that won’t dull the blade.

Single Knife Slitting

Single knife slitting machines use a stationary blade and a hydraulically powered feed of material to slit and rewind the product. It can work with most rolled plastics, tapes, films, or natural materials.

Zero Tension

Some materials respond poorly to tension, which can lead to stretching or imprecise cuts during both the slitting and rewinding processes. Zero tension machines can minimize the wound-on tension to zero or near-zero levels.

Shear

Shear slitting uses two rotary knives at once to cut material, producing the same effect as a pair of scissors. This process is ideal for heavier paper, foil, laminates, and films.

Perforating

Perforation processes cut through material by punching or stamping through it with enough force to cut it. This process can create holes or decorative images.

Spool Winding

Spool winding processes direct slit films and other rollable substrates around a circular spool. We use state-of-the-art equipment to wind long lengths of material with precision so the slit product is undamaged and secure during storage.

Surface Winding

Surface winders use cylinders to help guide sheets of material into place around a spool or to unspool material for controlled applications and cutting.

Core Winding

Roll defects are often caused when the winding is soft or imprecise near the core. We start every winding process with an accurate core and precisely chosen tension levels.

Industries and Applications

We serve clients in a diverse range of industries, including:

- Aerospace

- Automotive

- Appliance

- Biotechnology

- Construction

- Distribution

- Electrical

- Home Furnishing

- Medical

- OEM

- Packaging

- Pharmaceutical

- Printing

- Recreational

Our team can help recommend the right slitting and rewinding methods for any material to ensure the best outcome for your project.

Slitting Services and More From Sun Process Converting

At Sun Process Converting, we are committed to quality. Our company is ISO 9001:2015 certified, and we maintain a rigorous quality control process to ensure every project meets its specifications. We have also adapted our processes to use safe practices for our team, our clients, and our products during the COVID-19 pandemic. For more information, or to get started on your slitting and rewinding solution, contact us today.

Slitting Specifications:

- Score

- Shear

- Rotary

- Perforating

- Razor Slitting

- Single Knife

- Zero Tension Slitting

- Core Winding

- Spool Winding

- Film Rewinding

- Surface Winding

- Minimum Slit Width: .0625″

- Maximum Slit Width: 80″

- Minimum Material Thickness: .5 mil (.0005″)

- Maximum Material Thickness: 50 mil (.050″)

- Maximum Roll Diameter 40″

- Maximum Roll Weight: 1,500 lbs

- Core Diameter: 3″ and 6″

- Adhesive Tapes

- Industrial Aluminum Foil

- Cloths

- Cork

- Felt

- Foam

- Paper

- Pressure Sensitive Products

- Stainless Steel

- Masking

- Medical

- Teflon

- VHB

- Aerospace

- Automotive

- Appliance

- Biotechnology

- Construction

- Distribution

- Electrical

- Home Furnishing

- Medical

- OEM

- Packaging

- Pharmaceutical

- Printing

- Recreational

AS – Aerospace Industry Standard

ASME – American Society of Mechanical Engineers

ASTM – American Society for Testing and Materials

CSA – Canadian Standards Association

DOT – Department of Transportation

FAA – Federal Aviation Administration

FDA – Food And Drug Administration

ISO 9001:2015 – International Organization for Standardization

Mil-Spec Military Specifications

NADCAP – National Aerospace And Defense Contractors Accreditation Program

QS – QS Is a quality standard developed by the Automotive Industries

RoHS – Restriction Of Hazardous Substances (Compliant)

SAE – Society of Automotive Engineers

TS – Technical Specifications, used with ISO