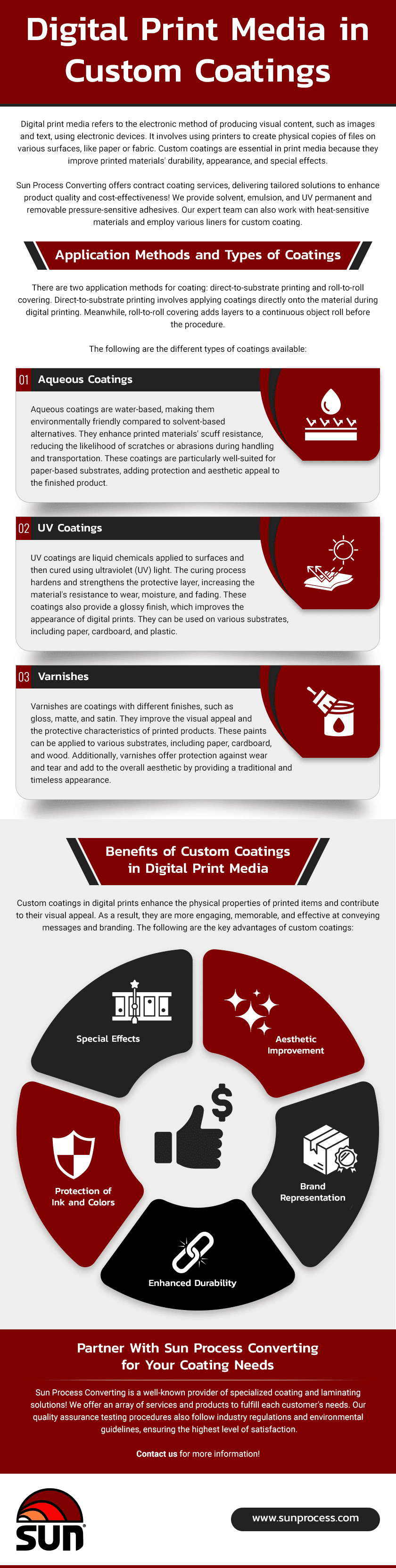

Digital print media refers to the electronic method of producing visual content, such as images and text, using electronic devices. It involves using printers to create physical copies of files on various surfaces, like paper or fabric. Custom coatings are essential in print media because they improve printed materials’ durability, appearance, and special effects.

Sun Process Converting offers contract coating services, delivering tailored solutions to enhance product quality and cost-effectiveness! We provide solvent, emulsion, and UV permanent and removable pressure-sensitive adhesives. Our expert team can also work with heat-sensitive materials and employ various liners for custom coating.

Application Methods and Types of Coatings

There are two application methods for coating: direct-to-substrate printing and roll-to-roll covering. Direct-to-substrate printing involves applying coatings directly onto the material during digital printing. Meanwhile, roll-to-roll covering adds layers to a continuous object roll before the procedure.

The following are the different types of coatings available:

Aqueous Coatings

Aqueous coatings are water-based, making them environmentally friendly compared to solvent-based alternatives. They enhance printed materials’ scuff resistance, reducing the likelihood of scratches or abrasions during handling and transportation. These coatings are particularly well-suited for paper-based substrates, adding protection and aesthetic appeal to the finished product.

UV Coatings

UV coatings are liquid chemicals applied to surfaces and then cured using ultraviolet (UV) light. The curing process hardens and strengthens the protective layer, increasing the material’s resistance to wear, moisture, and fading. These coatings also provide a glossy finish, which improves the appearance of digital prints. They can be used on various substrates, including paper, cardboard, and plastic.

Varnishes

Varnishes are coatings with different finishes, such as gloss, matte, and satin. They improve the visual appeal and the protective characteristics of printed products. These paints can be applied to various substrates, including paper, cardboard, and wood. Additionally, varnishes offer protection against wear and tear and add to the overall aesthetic by providing a traditional and timeless appearance.

Benefits of Custom Coatings in Digital Print Media

Custom coatings in digital prints enhance the physical properties of printed items and contribute to their visual appeal. As a result, they are more engaging, memorable, and effective at conveying messages and branding. The following are the key advantages of custom coatings:

Aesthetic Improvement

Coatings can improve the aesthetic appeal of digital prints by incorporating different textures, finishes, and effects like glossiness or matte surfaces. This personalization often goes beyond the ordinary, which results in a visually appealing and distinct printed item. Custom coatings also create a multi-sensory experience that engages the audience’s senses and leaves a lasting impression.

Brand Representation

Companies can ensure a consistent and unique visual experience across their materials by integrating brand-specific coatings. This strategic customization fosters a recognizable brand image and portrays a professional and dedicated approach to design and communication.

Enhanced Durability

Custom coatings improve the durability of digital print media by adding an extra layer of protection. This topcoat protects against moisture, UV radiation, and physical wear. As a result, printed text retains its vibrancy and integrity over time, ensuring that the design stays clear and engaging even in challenging environments.

Protection of Ink and Colors

Aqueous and UV coatings retain the quality and brightness of the ink and colors utilized, ensuring the long-term durability of printed goods. This protection shields against common issues like fading, smudging, and color degradation due to exposure to environmental factors.

Special Effects

Specialized paints facilitate the application of distinctive features like raised textures and spot varnishes, introducing tactile and visual contrasts to the surface. These effects strategically highlight specific design elements, which effectively capture the viewer’s attention and enhance the content’s overall impact.

Partner With Sun Process Converting for Your Coating Needs

Sun Process Converting is a well-known provider of specialized coating and laminating solutions! We offer an array of services and products to fulfill each customer’s needs. Our quality assurance testing procedures also follow industry regulations and environmental guidelines, ensuring the highest level of satisfaction.

Contact us for more information!