Some companies lack the capacities and necessary equipment to coat their materials, requiring them to rely on toll coating manufacturers. The toll coating process occurs when an organization hires a third party to coat its products or components. It typically provides opportunities for cost savings when entering a new market or creating new products and ensures that the company can access reliable equipment, operations, and expertise to meet specific material and coating requirements.

This article will dive into the toll coating process and the advantages of partnering with a toll coating manufacturer.

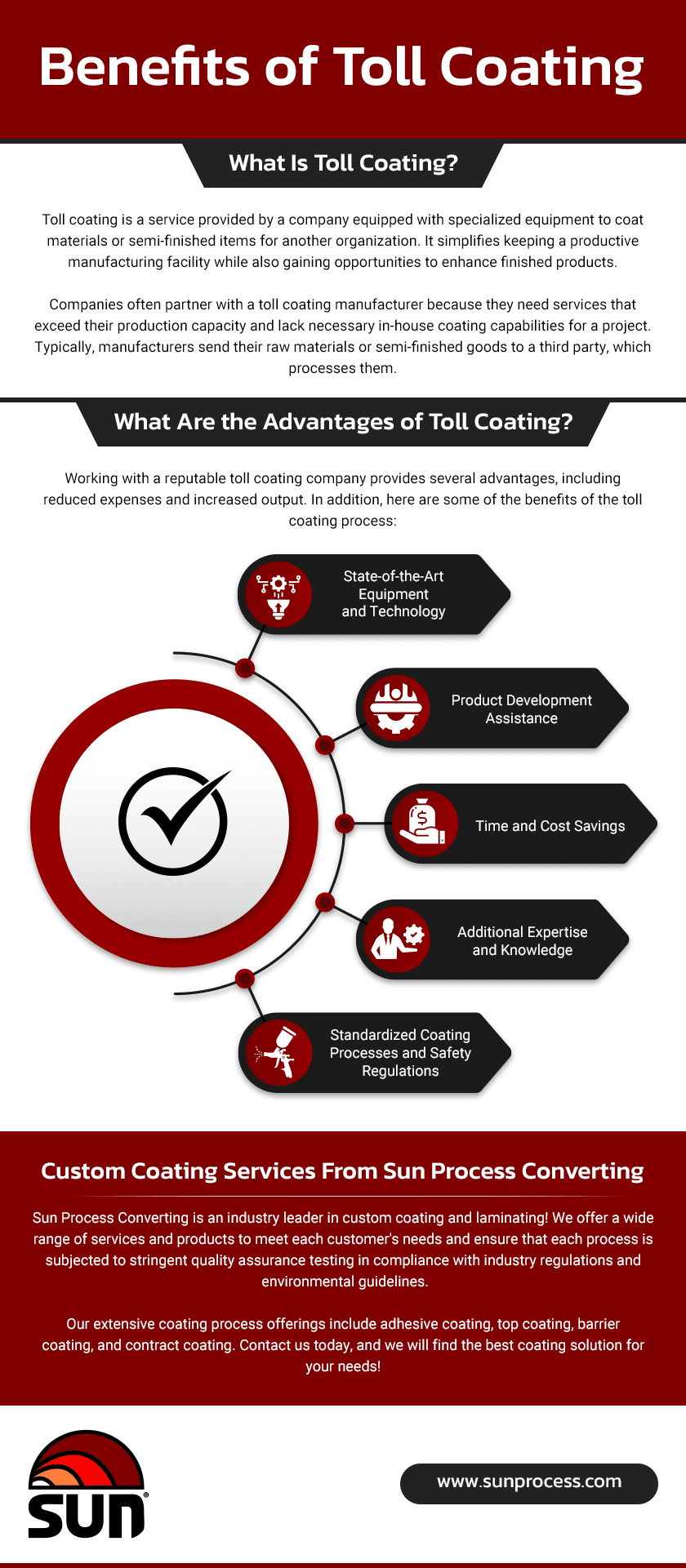

What Is Toll Coating?

Toll coating is a service provided by a company equipped with specialized equipment to coat materials or semi-finished items for another organization. It simplifies keeping a productive manufacturing facility while also gaining opportunities to enhance finished products.

Companies often partner with a toll coating manufacturer because they need services that exceed their production capacity and lack necessary in-house coating capabilities for a project. Typically, manufacturers send their raw materials or semi-finished goods to a third party, which processes them.

What Are the Advantages of Toll Coating?

Working with a reputable toll coating company provides several advantages, including reduced expenses and increased output. In addition, here are some of the benefits of the toll coating process:

State-of-the-Art Equipment and Technology

It is no longer necessary to purchase costly machines and tools because a reliable toll coating manufacturer is equipped with the appropriate cutting-edge equipment for various coating processes, including gravure coating and slot-die coating.

Product Development Assistance

Toll coating manufacturers provide product development assistance and act as extensions of the customer company to ensure that it thrives and succeeds. They typically begin by understanding the client’s needs before laying out the best plan for achieving those goals.

Time and Cost Savings

Before beginning the coating production process, toll coating manufacturers create trial batches for verification purposes and to maintain standards. This process allows technical, coating, or quality issues to be dealt with immediately, avoiding delays in production or increased costs.

Additional Expertise and Knowledge

Toll coating partners offer more than just equipment, amenities, and human resources. They employ skilled, knowledgeable professionals who work collaboratively with equipment operators to optimize production. These professionals are also updated on processes and technological advancements that provide efficiency improvement and quality enhancement opportunities.

Standardized Coating Processes and Safety Regulations

Toll coating companies have standardized work procedures to coat products in the safest, simplest, and most effective manner based on the client’s specifications. They must also meet quality and safety standards, ensuring a safe work environment.

Custom Coating Services From Sun Process Converting

Sun Process Converting is an industry leader in custom coating and laminating! We offer a wide range of services and products to meet each customer’s needs and ensure that each process is subjected to stringent quality assurance testing in compliance with industry regulations and environmental guidelines.

Our extensive coating process offerings include adhesive coating, top coating, barrier coating, and contract coating. Contact us today, and we will find the best coating solution for your needs!